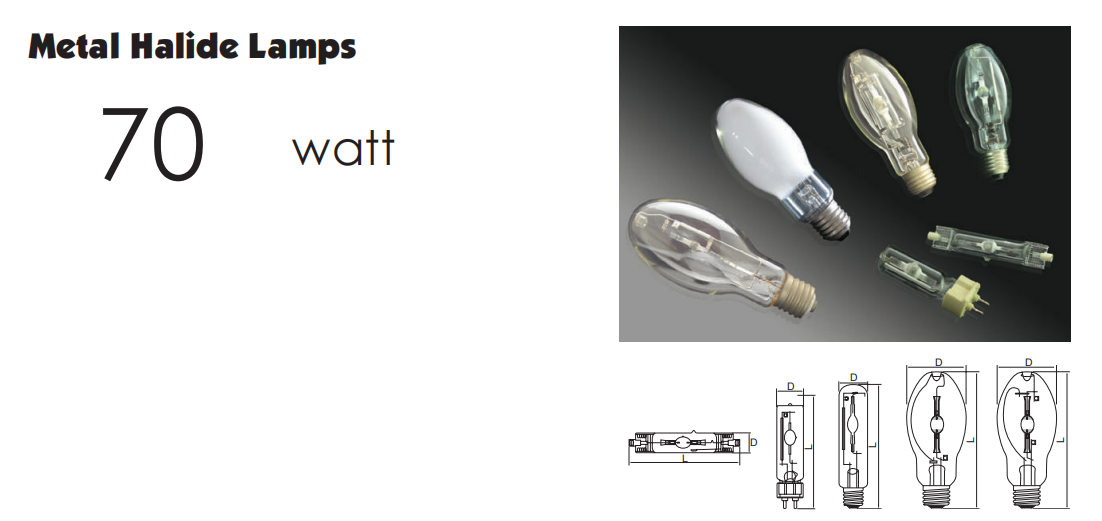

[China Aluminum Network] Air bubbles on the surface of aluminum alloy profiles are a common issue that can occur due to trapped air or gas within the aluminum billet during the extrusion process. As the material is heated and pushed through the die, this internal gas expands, causing the surface of the profile to bulge and form defects. These bubbles not only affect the aesthetic appearance of the product but can also weaken its structural integrity. Metal Halide Bulb A Metal Halide Bulb, also known as a Metal Halide Lamp, is a type of gas discharge lamp that produces light by passing electrical currents through a mixture of mercury and metal halides. It is known for its high luminous efficacy, long lifespan, and good color rendering index, making it a popular choice for various industrial and commercial applications Metal Halide Bulbs are widely used in: metal halide bulb,400 watt metal halide bulb,250 watt metal halide bulb,1000 watt bulb,100 watt metal halide bulb Yangzhou M.T. New Energy & Lighting Group Co., Ltd. , https://www.mtstreetlight.com

To prevent this problem, several key steps should be taken:

1. Ensure that the internal gas content in the aluminum alloy cast rod is as low as possible by using high-quality raw materials and proper melting techniques.

2. Keep the surface of the aluminum alloy cast rod clean and free from oil, dirt, or other contaminants that could introduce additional gases during the extrusion process.

3. Regularly clean the extrusion barrel to remove any residual material or debris that might mix with the molten metal and create air pockets.

4. Maintain an appropriate temperature for the aluminum rod before extrusion. If the temperature is too high, it may cause excessive gas expansion and increase the risk of bubble formation.

5. Increase the excess pressure during extrusion to help compact the material and reduce the likelihood of air entrapment.

6. Carefully control the amount of lubricant used. Excessive lubrication can lead to uneven flow and trap air, contributing to the formation of bubbles.

By following these measures, manufacturers can significantly reduce the occurrence of air bubbles and improve the quality and performance of aluminum alloy profiles.

Key Features

Applications

How to solve the aluminum alloy bubble defects

4

7